BFS packaging represents a substantial improvement from the aseptic packaging of pharmaceutical and healthcare products and solutions.

Respond to: Correct filling is obtained by way of precise metering methods, control of filling stress, and synchronization Together with the container’s placement.

Particulars with the BFS process fluctuate by equipment product and producer. But all BFS types conduct the identical general functions. Listed here’s a check out how the BFS process operates with a rotary BFS device – particularly a bottelpack 460 created by Rommelag.

On top of that, various spaces in the employee parking loads are reserved for energy efficient automobiles as Element of our LEED certification.

The BFS method is commonly Utilized in the pharmaceutical market for various programs. These contain the filling of ophthalmic and inhalation medicines, nasal formulations, and parenteral vaccines.

A reduced processing temperature can make it easier to receive an acceptable floor temperature for filling,” clarifies Goll. PP could be used for medications that require terminal sterilization, as it might stand up to larger temperatures during the terminal sterilization process.

Yet again, we’re handling a approach that was not previously done so this was a primary of its variety for us working with a seller to make this,” he claimed.

Steadiness info such as aggregation, chemical degradation, affinity and leachables indicated no important variations between glass and ADVASEPT container programs. Although it is difficult to extrapolate from protein to protein, the study shown that BFS can be a practical and economical system to create aseptically filled biologic formulations.

Why are shipyards, homeowners and engineering companies all over the world specifying Roxtec seals as their standard Answer for pipe penetrations? For the reason that we obstacle the normal sealing solutions and offer a top-quality alternate. Let's tell you about how.

This new here process provides flexibility even though keeping the large aseptic assurance concentrations supplied by the closed parison technology. Other additions involve automated vial inspection methods that perform IPC tests that are generally finished by hand, incorporating repeatability and the opportunity to give direct comments to your BFS system. Automatic particle inspection for injectable solutions has also been launched.

This process gives substantial operational advantages in excess of traditional glass filling traces, improving generation effectiveness and minimizing contamination risks.

Both of those shuttle and rotary devices are regarded Superior aseptic manufacturing procedures while in the pharmaceutical technology business.

The technology can then be leveraged For brand spanking new marketplaces, and change just how a product is shipped to the affected person. It really is apparent while in the creation check here of recent container closures that satisfy particular patient demands, such as closures with various ports, or even a flat structure that matches in a additional compact delivery machine. Finally, the technology facilitates container patterns that will provide items much more successfully.

The rotary BFS machines produced by Rommelag® that ApiJect largely types its technology for various likely positive aspects more than more common fill-end procedures, which include:

Rick Moranis Then & Now!

Rick Moranis Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Rachael Leigh Cook Then & Now!

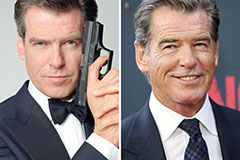

Rachael Leigh Cook Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!